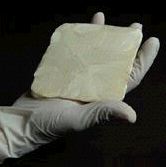

The HemCon™ hemostatic bandage (HemCon, Portland, Oregon, USA) (www.hemcon.com).

Preparation of the bandage involves a careful process of freeze drying which creates an ultrastructural architecture that is critical to good bandage performance. As a quality control measure, we have been developing optical methods to assess the on-line manufacturing process for these bandages.

The preparation of the bandages is accomplished by a freeze-drying process that generates ultrastructural lamina within the bandage. The freezing and sublimation of water concentrates the chitosan into laminar structures on the scale of 10-100 μm. There is a porosity associated with the bandage when its manufacture is completed. The orientation of the lamina is important. If the lamina are oriented vertical to the surface, there is good absorption and adherence to the wound. If the lamina are oriented horizontal, the adsorption and adherence are less effective.

The bandage is dry and porous when their hermetically sealed packaging is opened, and the bandage is applied to the wound with pressure. The bandage ultrastructure is critical to its ability to absorb blood and to adhere to a wound.

In this study, optical coherence tomography (OCT) was used to image the bandages. The study learned that in "good" bandages OCT sees a porous subsurface structure due to the vertical orientation of the lamina. In "bad" bandages, OCT shows horizontally oriented lamina that seal the bandage surface and prevent effective absorption of blood and adherence to a wound.